Satisfied clients

Pre Engineered Buildings

Described in few words, pre-engineered buildings are ideal for any non-residential low-rise building. Applications of pre-engineered buildings are numerous. Browse our project library to see pictures of a selection of our 95,000 buildings around the world.

The pre engineered construction system is undoubtedly one of the fastest growing construction systems in the world. The benefits it offers win over all parties involved in the project. After all, it can withstand a construction system that offers speed, quality and value.

Pre-engineered buildings, compared to conventional steel buildings, offer numerous advantages especially when it comes to low rise buildings. In addition to the lower initial cost and faster delivery, you will only have to deal with one party, Reacon Systems, for the design and fabrication of buildings.

Build Fast and Build Smart

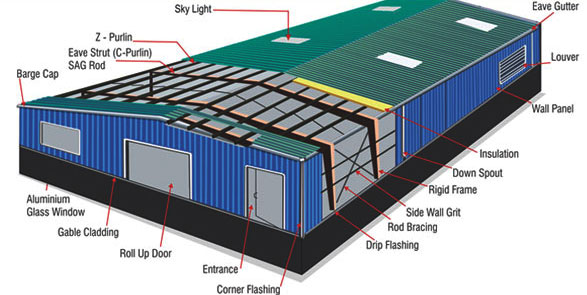

The Pre-engineered Buildings Structures are custom designed, precision engineered with minute detailing so as to ensure the efficiency of the final structure. These are lightweight with good and (of) high strength, making it easy to erect and will meet any weather conditions. The PEB´s are flexible, durable and adaptable. Recon System Pre Engineered Buildings are supplied with a very efficient external and internal drainage system

Recon System Metal Roof Structures can be built in minimal time and thus makes it an ideal choice to make all non-residential, large-scale and low-rise buildings for a long service life.

We, Reacon System provide these Steel Roof Structures (PEB´s) with a variety of structural and non-structural additions based on the customer´s specific requirements and design. We provide turbo vents, trusses, fascias, color coated roof sheets, daylight sheets, etc.

Advantages of using our Pre Engineered Building Structures:

- Economic & Cost Effective

- Factory Controlled Quality

- Durable

- Longevity

- Flexibility in expanding

- Environmentally friendly

- Faster Installation

Pre Engineered Buildings are custom made to suit a wide range of application in different industry sectors. It largely depends upon the requirement of the customers. They are also called Pre-Engineered Metal Buildings (PEMB) in some industry sectors. These metal buildings are different from conventional buildings in ways like speed in delivery and erection, flexibility in expansion and withstand severe weather conditions. We are a one-stop solution provider for all your structural needs and have products ranging from Porta cabins, Canopies, Mezzanine Floors, Stairs, etc. Having an experience of over two decades in this industry. We truly comply with all the ISI specifications while designing and manufacturing all our structures which ensure all-out safety and are quite economical as well, as we incorporate quality raw materials and sheets in their making.

Over the last few decades pre-engineered steel and metal buildings have become quite popular in the construction industry due to its flexibility, durability, and adaptability over. These factors have made steel one of the most sought after materials for building construction.

Our customer has a large choice for sheet material which can suit their budget as well as requirements such as pre-coated sheets, Sandwich Panel GI sheets, Fiber sheets, and Polycarbonate Sheets. In the pre-engineered building systems, one has the flexibility to accomplish an indefinite array of building configurations, custom designs, requirements, and applications. Factory sheds, warehouses, greenhouses, community halls and canopy, etc., are some of the ways where the PEB systems can be applied.

Structural Systems for PEB

It’s the structural system that determines the speed and flexibility of the pre-engineered steel/metal buildings. Steel column and beam segments fabricated and painted in a factory and that are merely attached together at the site are part of this system. The beams and columns having an end plate with holes for attaching at both ends are custom fabricated I-section members. Their making includes steel plates that are cut as per desired thickness and then welded together to make I sections. CNC machines are used for cutting and welding due to the speed and precision they offer. The operators just require feeding a CAD drawing of the beams into the machine. As a result of this production line style of work, the speed and consistency in fabrication enhance to a great deal. Forgetting optimal structural efficiency, one can tailor the shape of the beams as well. The beams are deeper where the forces are greater and shallow where they aren’t. This type of construction is different from the conventional ones.

PEB composition

Our customer has a large choice for sheet material which can suit their budget, as well as required such as Each piece of the PEB system, is quite similar. A crane is used to lift the painted steel sections, and they are then attached together by construction workers who climb to a suitable position. In the construction of huge buildings, we make use of two cranes that work from both ends. When the job of one crane is done, it’s taken away with the other finishing the work. This construction demands the installation of around 6 to 20 bolts that need to be tightened further so as to accurately match the amount of spin using a spin wrench.

We also take service contract for following work:

- Maintenance for shed and building structure

- Roof Sheet replacement by color coated sheet

Features that makes PEB valuable :

- Competitively priced

- Quality and innovation assurance

- Provision for easy future expansion

- Fastest delivery time & speedy erection

- Transported in a knockdown condition

- Low maintenance cost

- No welding facility required at the site

- Re-locatable and re-workable

- Attractive modern appearance

- Insulated to suit various weather conditions

- Ability to withstand seismic forces